1 – INTRODUCTION

The idea behind the elaboration of this document was to provide our worldwide commercial teams a better understanding of the possibilities and benefits of using LithoNutri Micron in a wide range of applications in aquaculture. The use of some pictures was decided to offer the readers a better “visualization”

of the several different situations our teams will face sooner or later, and accordingly to their local characteristics and eventual issues. Some tables were also included to ensure and highlight their sources, as well as to consolidate the information.

There are many other specific topics we can deeply develop. From aqua nutrition to water

management, many topics were not yet developed such as the anti-nutritional factors derived from plantbased inclusion increase in fish feed and shrimp feed; animals’ health improvements using LithoNutri Micron blends; the use of insect meal and yeast based meal, and their mineral supplementation requirement to achieve a better nutritional balance and develop the best solutions according to the specific species

requirements, geographical locations, production systems in use etc.

Probably a good way to find applications to one product is to understand it’s utility and find the

existing gaps to introduce it into the market. When we talk about the product’s utility for fish, shrimp and/or ornamental fish, the mode of action and the dosage should be addressed to the specific species and the specific farming production systems. Additionally, the use of LithoNutri Micron in aquafeed formulations should be suggested according to the formula requirements and all the efforts to explain formulators about the crucial importance not only linked to the Calcium and Magnesium percentage and content, but mainly focusing on the micro mineral’s bioavailability and animals’ requirements.

To achieve our goal and better understand LithoNutri Micron ’s suitability, we need to remember

some of its proprieties. Connecting and linking aquaculture fundamentals, applied ecology and species-specific production systems with LithoNutri Micron composition and structure, a very large range of application possibilities arises.

It is also necessary to know the specific environment the animals live in nature and how are their natural lifecycle. The knowledge of the natural functioning of their environmental ecosystems is also necessary. Mother nature teaches us how to succeed when farming one species or another. Their natural habitats show us all the answers.

Hence, it is deeply recommended the knowledge of the natural conditions the aquatic animals live in nature and find ways to replicate all these biological and physic-chemical conditions using LithoNutri Micron to achieve the artificial conditions that fishes, shrimps, or ornamentals fishes claims to.

2 – AQUACULTURE MAIN VALUE-ADDED SPECIES

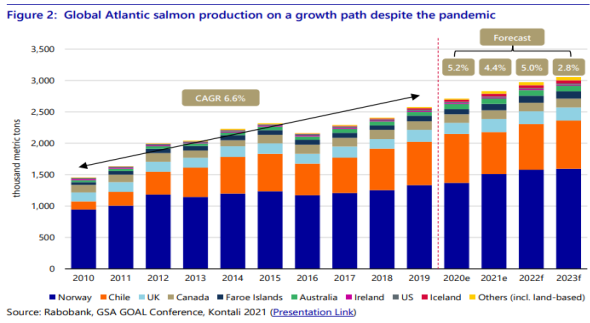

Penaeid shrimp, Salmon farming and Tilapia farming are three main global aquaculture derived

aquaculture’s seafood protein derived products for human consumption. In APAC zone, for instance, if we consider a focus on Thai aquaculture production and trade, the White Leg Shrimp (Litopenaeus vannamei) is far the biggest business, followed by the freshwater Tilapia (Oreochromis niloticus) rearing farms.

In Latin America (“Latam”) Zone, we need to reinforce that Ecuadorsurpassed China in the production of the White Leg Shrimp (Litopenaeus vannamei). Ecuador, alone, produced more than 1 million tons and traded almost USD 8 billions). Just like in Thailand, the second biggest inland business in Latam zone is also the freshwater Tilapia farming. Brazil is the biggest market and the world’s fourth biggest producer (behindChina, Indonesia, and Egypt).

Salmon farming is the more mature worldwide aquaculture market. Countries as Norway, Scotland, Ireland, and many other countries in north Europe have a very well stablished offshore farming systems, from brood stock genetic improvements to inland freshwater hatcheries, until reaching their size grade to get moved to big, robust, and technologically advanced facilities. The United States, Canada and Iceland are

already some of the biggest Salmon (Salmo salar) with a consistent year-by-year growth. In Latin America, Chile is far the biggest Salmon producing country. Chilean Salmon farming is also a very mature industry with the main genetic improvement, nutrition, vet-pharma, and specialties’ multinational companies (Cargill, Zoetis, Alltech, Lesaffre, INVE etc.) competing on for a share of this huge market. Australia and New Zealand already have started Salmon farming offshore, with many investments being made to faster develop this strategic business. By the other, even Middle Eastern countries like United Arabic Emirates, Qatar, Saudi Arabia are extremely excited for the surreal investments already maiden (and in the ones in course) to grow inland Salmon in artificially controlled facilities.

2.1 – Penaeid Shrimps

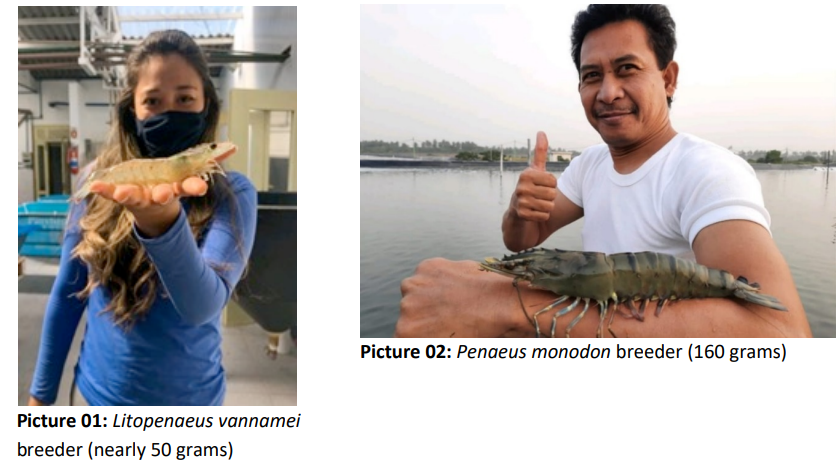

The worldwide most produced shrimp is commonly known as white leg shrimp (Litopenaeus

vannamei), followed by the Black Tiger Shrimp (Penaeus monodon). For more than three decades, white leg

shrimp have been the greatest volume. It is a smaller size shrimp when compared with the black tiger Penaeus

monodon, whose traded prices are higher but, unfortunately, riskier due the longer time crop duration and

the consequent susceptibility to diseases and uncontrolled water ponds’ environment, among many other

issues’ possibilities.

Worldwide, as coastal areas are used for many activities rather than only shrimp farming, new production

systems needed to be developed to rear Litopenaeus vannamei, Penaeus monodon, P. japonicus etc.).

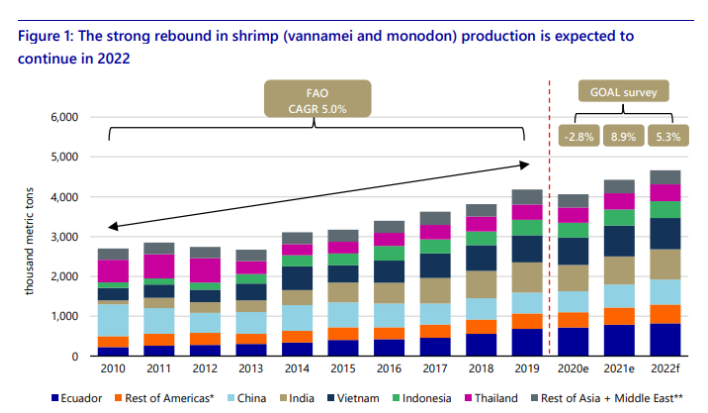

According to the main global players, in 2021, Litopenaeus vannamei + Penaeus monodon accounted for more

than 80% of the total shrimp farming production globally.

Thus, a lot of attention we should give to these species in order to technically succeed when finding ways to

implement new production systems and its requirements in terms of soil conditioning, organic matter

mineralization, soil pH stabilization, pond’s water alkalinity and hardness increase and stabilization; natural

pond’s productivity booster; water pH stabilization, higher phytoplankton, zooplankton and zoobenthic

diversity and density without algae blooms (cyanophyte’s blooms), amongst many other environmental and

nutritional aspects.

Picture 01: Litopenaeus vannamei breeder (nearly 50 grams)

Picture 02: Penaeus monodon breeder (160 grams)

The ecosystems where Penaeid shrimp lives along their life cycle, here called as coasts, estuaries,

mangroves, deltas etc., are quite different from the deep sea. As learned in advance, when shrimp

metamorphoses from nauplii to zoea to Mysis to post-larvae to juveniles, the coastal area is where they’re

naturally looking for. It is rich in nutrients, plankton (zooplankton, phytoplankton, zoo bents, periphyton etc.),

normally has a brownish color, and is rich in live foods to supply their body growth and health on its way back

to sea/deep sea, to re-start a new F1 life cycle. Indeed, coastal areas are a treasure, a repository of nutrients.

2.1.1 – Coastal areas (mangroves/estuaries)

Once we understand and consider that coastal areas are the ones Penaeid are looking for since their

early stages until they become old juveniles (which are the size/weight we grow and harvest them on a profit

way), starting their deeper sea migration as an adult to maturate until they become breeders and start a new

life cycle. We should consider the intrinsic characteristics this ecosystem presents, to allow usto try to mimicry

them on our different aquaculture rearing production systems. According to Glen Cho (2022), a well-known

Integration Aquaculture Farm Designer from Seoul National University, appropriate farming systems should

be applied accordingly to the target species you are studying or rearing, either on a small or large scales.

Besides coral reefs, coastal areas so called mangroves and/or estuaries are the richest habitats in

terms of nutrients availability, micro algae, bacteria, yeasts, invertebrates and vegetal and animals’

biodiversity. The natural environment for a wide range of macro and micro flora and fauna throughout their

nature life cycles.

Pictures 3 and 4: Estuary and Mangrove areas in Thailand

2.1.2 – Estuaries and mangroves’ most common characteristics

Also called “the mouth of the rivers”, estuaries and mangrove areas, are the zones where the

nutrients’ enriched rivers’ water are mixed with macro and micro minerals’ seawater availability. These

different water sources, when mixed, leads to the brackish waters’ generation. The tides, the moon phases,

the marine currents, and the upwelling tides, for instance, makes them unique ecosystems.

Not seldom, when walking near by mangrove areas on a low tide, we can easily smell sulfidic acid

(H2S), what means that the nutrient availability carried out to those areas, forsome time between tides, didn’t

have enough Oxygen availability, allowing anaerobic bacteria to thrive and produce sulfidic acid (H2S). Oxygen

supply (>3-4 ppm) enables nitrifying bacteria such as Nitrosomonas (Nitrate to Nitrite) and Nitrobacter (Nitrite

to free nitrogen) to mineralize natural organic matter ecosystem’s inputs. Thus, with organic matter to be

mineralized, the muddy soils of mangroves are acid, presenting low pH levels. Therefore, shrimp ponds’

bottom pH at farms built nearby (or even inside) the mangroves’ areas are also acid soils and/or muddy acid

soils and need to be neutralized.

We must remember that during this phase, in nature, shrimps are at their early stages, in different

level at the water column to catch their food. At this stage, they are not yet benthic crustaceans, and, for this

reason, they are able to live without the need for a substrate to lay on. After they become a juvenile and/or

an early adult, they naturally swim in their way to the sea and deep sea, where the natural bottoms/substrates

are neutral or slightly alkaline and, thus, more suitable to their body’s comfort. Nevertheless, on this old

juvenile and young adults, Penaeid shrimps are now hunted by their natural ecosystems’ predators such as

carnivorous fishes, for instance.

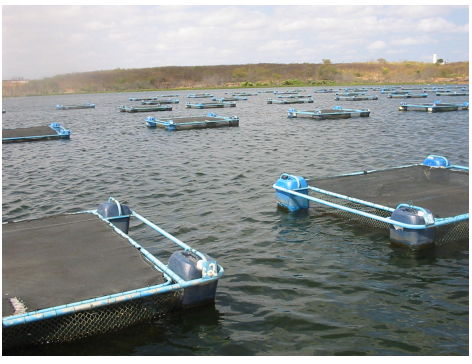

Shrimp farming started in mangrove areas all around the world and, despite to the increased

technological improvements, we can still find shrimp farms with large ponds in countries such as Ecuador,

Colombia, and Brazil.

Picture 5: Extensive Shrimp Farm in a mangrove are in Brazil.

The picture shows very large ponds with an empty one, that necessarily presents a high organic matter accumulation due to the greenish dead cyanophyte settled at the pond’s bottom. This type of soil normally has a very acid pH that needs to be stabilized. Applying LithoNutri Micron in such soils will not only increase the soils’ pH. It will, additionally, while buffering the ponds’ soil, release bioavailable trace elements to boost ponds’ natural food production and organic matter mineralization. The microminerals and the organic content and diversity also plays a key role to enable the biochemical and physic-chemical reactions to well succeed. Very often, seaweeds like Lithothamnium are places shrimps feel more comfortable to lay on, once they do not only can get natural food and minerals, as well as they can run out of their predators or even hide themselves from predators at the seaweeds/macroalgae. Adult lobsters do the same as the shrimps. They use seaweeds to hide themselves from bigger predators’ fishes, by the time they supply their minerals’ bodies requirements to have the ideal macro and micro minerals contents so that they can maturate their reproductive organs, copulate, and breed healthy eggs who will restart a new shrimp (or lobster) generation. ndeed, shrimp and lobsters’ wild catch are done at sea, near by the coastline and normally on a seaweed substrate bottom, where they are able to get food from the nearest estuary areas, as well as they can absorb minerals from seaweeds and sea water (through their gills), on a much more stable environment in terms of water parameters’ stability, neutral and/or slightly alkaline bottom/substrates, necessary to prepare themselves to go even further into the sea to complete their life cycle journey. If we use this information to characterize Penaeid shrimp’s natural environments and their different life stages and different requirements, we should conclude that: A – Natural shrimp eggs, zoea, Mysis, larvae, post-larvae, juvenile and adult shrimp comes from healthy and nutritionally male and female breeders whom, in nature, had the chance to eat the richest possible nutrients, and absorb the most important macro and micro minerals’ requirements. B – Mangroves’ muddy soils are acid and, not seldom, very acid. Therefore, after becoming an old post-larvae and/or young juvenile, Penaeid shrimps migrates from the brackish water columns, where they use to swim up and down to find food, and swims back into the sea to find a comfortable pH soil substate so that they can rest and lay on the founded substrate, and not losing their natural migration capacity to come back to the estuaries to get their food and then, swimming back to the seaweed protected zones, where they’ll absorb trace elements and micro minerals. C – Additionally, we need to remember that old juveniles and young adults (10 grams to 25 grams, average body weight – ABW) for Litopenaeus vannamei (white leg shrimp), in nature, are the commercial profitable size/weight, and 30 grams to 50 grams, average body weight – ABW for Penaeus monodon (black tiger shrimp). Therefore, their food (proteins, lipids, and vitamins) as well as their macro and micro minerals’ requirements grows as shrimps body weight increases. D – Last but not least, it’s also necessary to understand that the physic-chemical and biological water stability required by shrimp are directly proportional to the shrimp health status and consistent growth rates, the key parameters to succeed when farming shrimp. Water parameters such as Redox potential, oxygen availability, stable pH, total alkalinity and total hardness, ammonia, nitrate, nitrite, orthophosphate, bacteria load and species quantity and diversity are the main known variables to better manage shrimp health and growth.

2.1.3 – Different Shrimp Farming Rearing Systems

Nowadays, several different shrimp farming production systems coexists, since large extensive shrimp ponds with very low stocking densities ( 3 – 7 shrimps/m³), to a extensive/semi-intensive smaller (but still large) ponds, with a slightly higher stocking densities (8 to 15 shrimp/m³) artificial feed required (in a low amount), up to an intensive outdoors earthen ponds shrimp farms, with stocking densities that could achieve up to 100 shrimps/m³ or even more, and going further to an outdoors geomembrane-lined ponds, where stocking densities could get up to 250-300 shrimps/m³, as well as ultra-intensive indoors shrimp farms, with very small geomembrane-lined ponds inside a dark greenhouse, using stocking densities up to 2.500 shrimps/m³.

Picture 6: Extensive shrimp farm with large ponds and different watercolor e composition.

Picture 7: Brazil’s Biggest Semi-Intensive Shrimp Farm with 250 ponds of 4 hectare and stocking density of 50

p/m³.

Picture 8: Over Over-Eutrophicated Shrimp Geomembrane- Lined Aerated Shrimp Ponds in Guatemala.

This picture clearly shows Over-Eutrophicated Geomembrane-Lined Aerated Shrimp Ponds’ waters.

The green dead algae and foam means necessarily a high organic matter concentration will consume a lot of

Oxygen, will harmfully decrease the pH of both soil and water, and immediate providences must be taken to

help the reared shrimps to survive: Enough oxygen supply, probiotic bacteria input, live yeast input and a very

effective pH stabilizer like LithoNutri Micron are crucial to achieve this goal.

Picture 9: Ecuadorian mixed production system with high stocking density in small, aerated ponds (250

shrimp/m³) to produce 1-gram juvenile to be harvested and re-stocked on a bigger semi-intensive pond (30

shrimp/m³) until final harvest.

Picture 10: Intensive earthen ponds shrimp farm in Indonesia. Perfect water brownish color. Average

stocking density of 280 shrimps/m³. Fully aerated, bioremediated and water stabilized ponds.

Picture 11: Supe-intensive geomembrane-lined ponds (300 shrimp/m³) with paddle-wheel aerators, automatic feeder, healthy water quality with enough oxygen supply, balanced total water alkalinity and density and stable daily pH fluctuations in Brunei Darussalam.

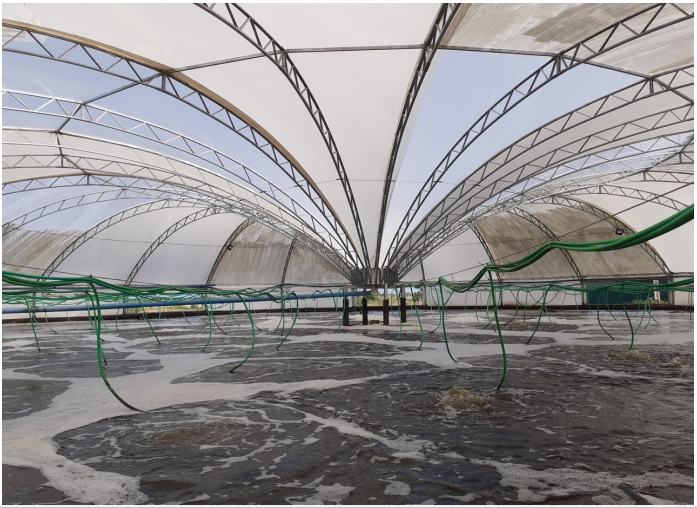

Picture 12: Chinese Intensive indoor geomembrane-lined ponds (250 shrimp/m³) with wave makers, paddlewheel aerators during the winter and thanks to the greenhouse temperature stability.

Picture 13: Brazilian Intensive indoor geomembrane-lined ponds (200 shrimp/m³) with paddle-wheel aerators, oxygen blowers and zero ppt salinity.

The greenhouse maintains water temperature stability while LithoNutri Micron provides bioavailable macro-minerals like Ca and Mg and releases the bioavailable essential microminerals to maintain water conditioning balance.

Picture 14: Intensive outdoors geomembrane-lined ponds (250 shrimp/m³) with 3 meters depth water column, paddle-wheel aerators in a RAS (Recirculating Aquaculture System) at one of Guo Liang’s farm facility in China.

All these production systems require different technification levels to succeed. Considering that we need to find gaps to introduce LithoNutri Aqua as part of an ideal protocol to our targeted customers, it’s clear that we need to well know their local reality and rearing production system to properly suggest the right LithoNutri Acqua® suggestive protocol. Hence, understanding what LithoNutri Micron is, and which benefits it brings to different shrimp rearing systems, is essential to find ways to address a wide range of possibilities.

2.2 – Fish Farming

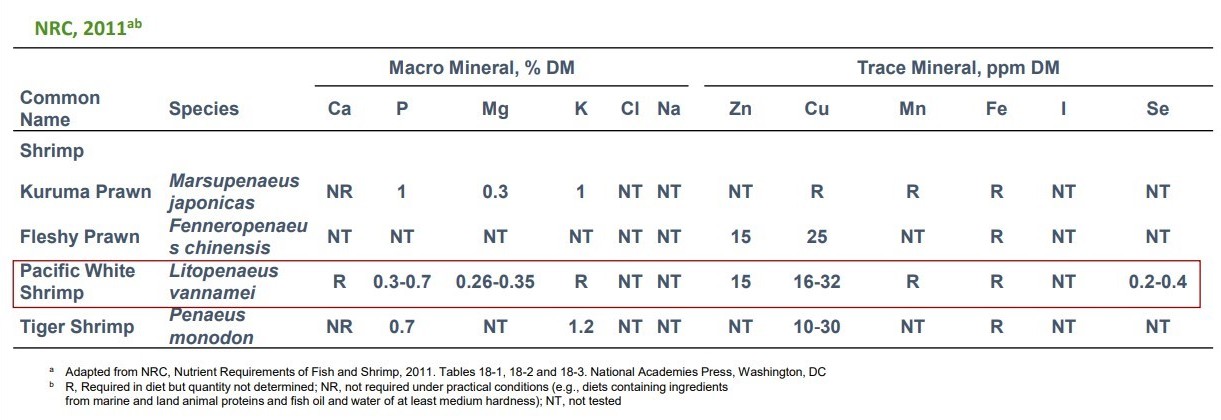

Aquatic animals have their unique physiological and osmoregulatory mechanisms to absorb and retain minerals from their diets and water. Research and development around mineral nutrition and requirement for farmed fish have been relatively slow and many gaps still exists in the knowledge of trace element requirements, physiological functions, and bioavailability from feed ingredients according to Lall et. al. (2021).

2.2.1 – Tilapia Farming

Picture 14: Intensive floating cage Tilapia Sample (Body Average Weigh > 1.2 Kg)

Quantitative dietary requirements have been reported for three macro minerals (calcium,

phosphorus, and magnesium) and six micro minerals (zinc, iron, copper, manganese, iodine, and selenium) for

some fish species. As in the case of the crustaceans, different species has, in nature, their specific comfort

zone, the ones we should mimicry to get healthy, environmentally stable, and profitable fish harvests. It is

clear so far that even rearing the same fish species, the production systems and consequent LithoNutri Micron

’s suitability applications shall be different.

If we agree Tilapia farm is the second major aquaculture business in Thailand, we easily notice that

Tilapia production are mainly reared in earthen ponds. From the other side, once we consider Brazilian tilapia

production, the 4th biggest global Tilapia producing country, we find out that the greatest, biggest, and more

professionalized farming systems are carried out at floating cages located at the main Brazilian suitable

freshwater reservoirs.

If the rearing system is carried out in earthen ponds, like in Thailand, some other LithoNutri Micron ’s

beneficial proprieties already exist, just like for pond’s bottom pH stabilization and its consequent macro and

micro mineral releasement and bioavailability. High Tilapia stocking densities such as 25-30 fish/m3 also tends

to dramatically drop the water pH, reaching an acid water environment and, thus, leading them to a stressful

condition, where eating (and growing) is not their immediate priority. The use of LithoNutri Micron in such

cases is highly recommended.

Picture 15: Intensive Earthen Tilapia Pond in Thailand. Cages are used to grow fingerlings into juveniles’ fish.

Picture 16: Fingerlings birds-free Earthen Tilapia Pond in Thailand.

Picture 17: Traditional Net Cages Tilapia Farm in Brazil. Volume = 2 m x 2 m x 1,5 m = 6 m³ where 700 juveniles are stocked.

Picture 18: Traditional earthen Tilapia Pond in Thailand. Green watercolor suggests the beginning of an ecologically eutrophicated environment.

Micro minerals and trace elements are not always considered while formulas, formulators and

formulations are being designed by traditional formulators. Nevertheless, micromineral deficiency signs in fish

includes (but are not limited) by reduced bone mineralization (Ca and Mg), anorexia, lens cataracts (zinc),

skeletal deformities (phosphorus, magnesium, zinc), fin erosion (copper, zinc), nephrocalcinosis (magnesium

deficiency), thyroid hyperplasia (iodine), muscular dystrophy (selenium) and hypochromic microcytic anemia

(iron).

Fish gills comprise over 50% of their surface area and are considered the major route of uptake of

waterborne minerals in freshwater. In saltwater, fish exhibit obligatory drinking as part of their overall

physiological osmoregulatory mechanism to maintain internal body fluids substantially hypotonic accordingly

to the external salinity of the saltwater.

Tilapia is also a filter fish, what means that while swimming throughout the water ponds, they absorb

planktonic organisms through their gills, and then they swallow the previously accumulated natural food at

their gills. Many times, however, buyers complain about fishes off flavor, and, in many cases, they are right.

Normally, reared fish off flavor are caused or closely linked with cyanophytes abundance/density on the water

rearing ponds. These micro algae normally grow due fish overfeeding when a lot of non-mineralized nitrogen

is released by the denitrifying bacterial process.

Applying LithoNutri Micron throughout the pond bottom surface (before filling it up), and maintaining

a weekly or bi-weekly LithoNutri Micron on the water will increase ponds’ minerals bioavailability, also

increasing other micro algae to grow such as Chlorophyceae, Rhodophyceae, Diatoms etc. Once this happens,

zooplankton density and diversity (rotifers, copepods, Cladocera’s etc.) will also increase, and this enriched

water planktonic organisms enables a better fish growth, health, and comfort, providing a stressless fish

production while reducing fish off flavor and leading to a higher farmers’ profit.

This means that even if we grow the same species, the production system used is the main indicator

we should consider applying LithoNutri Micron ®. When we grow Tilapia in floating cages, the only way we

have at our disposal is to introduce it into the system as a natural seaweed feed prebiotic. Indeed, LithoNutri

Acqua® has a powerful antioxidative propriety and an electrolytical honey-comb shaped structure. It is a

source of not less than 32% of bioavailable calcium, at least 3% of bioavailable magnesium and more than 70

different bioavailable microminerals and trace elements plus at least 4,5 ppt of its organic portion, composed

of 18 different amino acids, saccharides, and vitamins. .

2.2.2 – Salmon Farming

A deeper review on the salmon industry’ state of the art must be done to add it on the second version

of this document. By now, we’re considering mainly warm water aquatic animals. Therefore, absorption of

dietary minerals from the gastrointestinal tract is important in freshwater fish, whereas in saltwater fish, both

dietary and waterborne minerals are absorbed. The life cycle of anadromous fish like salmonids, for instance,

consists of freshwater and saltwater, where they gradually adapt to a marine environment and acquire

inorganic elements by drinking saltwater, just like marine fish

3 – AQUACULTURE AND LithoNutri Micron

LithoNutri Micron is a 100% organic certified seaweed-derived prebiotic, formed by Lithothamnium

marine algae, with multiple applications in shrimp and fish farming. Its honeycomb-shaped structure and its

organic-mineral composition ensures many beneficial proprieties with a wide range of characteristics that we

suggest being used. It is composed of more than 70 bioavailable microminerals, a significative bioavailable

Calcium and Magnesium content (Ca > 32% and Mg > 3%, respectively) plus 18 LithoNutri Micron amino acids,

saccharides, and vitamins (4.5 ppt).

Its use in excavated earthen ponds is recommended for the neutralization of the soil pH and the

consequent increase on bottoms soil’s Redox potential (ORP), in addition to the bioavailability of

microminerals released by LithoNutri Micron to boost natural zooplankton productivity, mainly at the

zoobenthic ponds’ soil/water interface areas.

Applied on the rearing water, LithoNutri Micron slowly settles down to the soil/water interface.

Once the ponds’ water pH is under 7, it means that the environment’s population are living on an acid water,

and the cationic LithoNutri Micron ’s microminerals ions composition, alongside with the Calcium (Ca) and

Magnesium (Mg) bioavailability, and the product starts releasing its microminerals’ composition while

buffering the water by stabilizing its pH through the total alkalinity and total hardness increase and

maintenance. Reducing daily pH fluctuations means that shrimps and fishes are saving energy to better deal

with their osmoregulatory and physiological processes.

The bioavailability of the trace elements’ contents, in addition to the organic matter composed by

18 amino acids, saccharides and vitamins, also promotes a balanced phytoplankton and zooplankton diversity,

avoiding cyanophytes over eutrophication blooms, which can lead to partial or total shrimp and/or fishponds’

mortality due to Insufficient dissolved oxygen supply on the water, also known as anoxia.

As an 100% organic certified seaweed-derived prebiotic,LithoNutri Micron have also being

successfully used for feed millers aiming to enhance the wide range of essential microminerals found at

LithoNutri Micron , as well as to achieve the best possible phosphorus and calcium ratio to the aquafeed

composition and nutritional balance. Nutritionists and aquafeed formulators have different software to

calculate the calcium and magnesium optimal supplementation. However, the quality and availability of the

raw material used for aquafeed not always calculates the non-digestible ingredients’ bioavailability, what

means that LithoNutri Micron supplementation is cost effective due to its natural bioavailability.

4 – APPLICATIONS AND DOSAGES

According to all information mentioned previously in this document, suggesting a dosage

recommendation is not an easy task. Nevertheless, our experience on shrimp and fish farming enables

ourselves to suggest some applications when using LithoNutri Micron .

| Thông số nguồn nước và lý hoá | Alves và

Melo, 2007 |

Wyk và cộng sự , 1999 | NUNES và cộng sự,

2005 |

Boyd, 1998 | ABCC,

2004 |

SLA, 2009 |

| Nhiệt độ (ºC) | 26 – 32 | – | 22 – 32 | 28 – 30 | 26 – 32 | 18 – 33 |

| Oxy hoà tan – DO (mg/L) | > 5 | – | > 3 | 6 to 10 | > 3,7 | 2,5 to 10 |

| pH | 7 to 9 | – | 6 to 9 | 8 to 9 | – | 7 to 10 |

| NH3 (mg/L) | < 0,3* | – | < 0,1** | 0,1 to 1,0*** | <0,12** | <0,20*** |

| NO3- (mg/L) | 0,2 to 20 | – | < 60 | 0,4 to 0,8 | 0,2 to 10 | 1,7 to 3,10 |

| NO2- (mg/L) | < 0,3 | – | < 1,0 | < 10 | < 0,1 | 0,003 |

| [PO 4 ] 3− (mg/L) | < 0,4 | – | < 0,5 | 0,1 to 0,3 | – | 0,66 |

| SiO2 (mg/L) | > 2 | – | > 1,0 | > 1,0 | – | 0,01 to0,2 |

| Chất diệp lục A (mg/L) | – | – | – | 0,05 to 0,075 | – | 5 to 20 |

| Độ mặn (ppt) | 15 to 25 | > 0,5 | – | 15 to 25 | – | – |

| Độ trong (cm) – Đĩa Secchi | 40 to 60 | – | 35 to 50 | 35 to 45 | – | – |

| Tổng độ kiềm (mg/L CaCO3) | – | > 100 | > 100 | 100 to 140 | – | 50 to 150 |

| Tổng độ cứng (mg/L CaCO3) | – | > 150 | > 150 | – | > 1000 | 5700 to 6600 |

4.1 – Earthen Pond Soil:

4.1.1 – Use from 250 to 500 Kg/Ha in a wet pond bottom soil and up to 100 shrimp/m³ after

disinfection and acids volatilization.

4.1.2 – Use from 500 to 1000 Kg/Ha on an acid muddy pond bottom (mainly founded on farms built

nearby mangrove and/or estuaries’ neighboring areas).

4.1.3 – Shrimp ponds with high iron concentration on their soil composition normally do not achieve

the expected average production, yield, and profitable results. Iron oxidation leads to very low shrimps’ pH

substrates. The chemical reaction (iron oxidation) “burns” the shrimp anthem’s, pleopods, pereopods and not

seldom, their exoskeleton.

These harmed tissues can open doors to opportunistic harmful bacteria and/or virus, weakening the

rearing shrimps and their immune-systems’ decreasing capacity, while producing free radicals on an instinctive

way to protect themselves from unknown organisms. These weakened animals are more susceptible to

diseases, they don’t eat as much as they could and, thus, their growth rates and moulting process are longer

and consequently they lead to a higher FCR increase.

Dosage – The LithoNutri Micron input shall be calculated after the Iron percentage on the soil is properly

sampled and analyzed. Depending on the iron concentration is measured, the correct dosage will be defined

accordingly. The total iron neutralization will be achieved after some crops using LithoNutri Micron when

preparing the pond soils for consecutives production cycles and it depends on the concentration found and

the LithoNutri Micron inputs. Not less than 1 ton of LithoNutri Micron per hectare will be necessary to achieve

Fe+2 and Fe+3 neutralization.

4.2 – Water Quality Enhancement

Due to very different environmental conditions such as water sources (rivers, lakes, artesian wells,

brackish water, salt water, hypersaline water) and farming production systems (extensive, semi-intensive,

intensive, super-intensive, RAS – Recirculating Aquaculture Systems, mixotrophic systems, multi-trophic

systems, bio floc systems etc.), we can easily conclude that each specific situation requires different technical

and managerial procedures to well succeed when rearing shrimp and fish.

Additionally, different researchers do not always agree on the ideal physic-chemical and

hydrobiological parameters normally used to maintain optimal water conditions. The table below is just an

example founded on the literature regarding optimal different variables according to different renowned

sources.

Thus, LithoNutri Micron input will vary according to the production system used by shrimp farmers

and normally will vary from pond to pond according to animals’ live stage, feed input, probiotic bacteria

quality, quantity, and its frequency of use, fertilizers use, dosage and composition, water exchange ratio

among many other factors that affects the water quality where shrimps are farmed.

The experience we have using LithoNutri Micron for water quality enhancement in different water

sources and productions systems enables us to suggest dosages accordingly. However, the best information

will be provided from the pond’s parameters checking and, regarding LithoNutri Micron specifically, total

alkalinity and hardness, daily pH fluctuations and redox potential are the main ones.

Hence, checking pH early morning (ideally before sun rise) and late afternoon (ideally after sun set)

will provide a wonderful information to the production manager and his/her staff members. The

photosynthetic process along the day directly affects the water pH levels, and a more stable pH along the day

is a strong indicator thatthe water condition is satisfactory. Nevertheless, the pH stability is intrinsically related

to the total alkalinity and total hardness of the water and the necessary oxygen supply.

Water samples need to be collected at least every two days to ensure total water alkalinity and total

water harness are stable and, ideally higher than 120 mg/L total alkalinity. When farm managers see a

decrease on the alkalinity levels, LithoNutri Micron need to be applied to recover alkalinity to the indicated

suggested level (120 mg/L). When alkalinity drops to levels below 100 mg/L, the time to recover it will be

longer and the shrimp health status may be affected, as well as its immunomodulation capacity, feed intake,

the conversion from feed to muscular tissue will also be impacted. The convergency of the mentioned water

parameters’ alterations may lead to weaker shrimps, more susceptible to diseases and with its committed

growth, leading to a longer crop duration and shrimps’ vulnerability, directly and negatively impacting the

profit.

Finally, shrimp farmers are encouraged to measure the redox potential, since this parameter enables

shrimp farm managers to evaluate the potential the ponds must oxidize and/or reduce the accumulated

organic matter. The higher the redox potential, the better ponds’ environment. Sediment redox potential

significantly affected the dissolved oxygen, TAN (Total Ammonia Nitrogen), NO2, NO3, and H2S concentrations

in the water. Whereas shrimp stocking density affected all water quality parameters except H2S concentration,

significant interactions between redox potential and stocking densities are observed in nitrite and alkalinity

concentrations. The significant effects of both shrimp density and redox potential on the sediment and water

parameters are known to directly affect the shrimp welfare (e.g., oxygen, ammonia, nitrite and H2S) indicating

that these variables are essential to shrimp pond management.

According to Boyd (2016), in aquaculture earthen ponds, the objective should be to maintain aerobic

conditions (redox above 0.5 volt or more at the sediment-water interface). When redox falls to around 0.2 to

0.3 volt, the color of the surface of the sediment (soil) will become darker (often dark gray or black). Normally,

water-soil surface layer is aerobic and of lighter color comparing to the anaerobic layer a few millimeters

below as revealed by swiping away the thin surface layer.

The color change is the result of the reduction of ferric iron (Fe+3) to ferrous iron (Fe+2) at a redox near

0.2 volt. The redox must fall to 0.0-0.1 volt before anaerobic bacteria begin to convert sulfate to sulfide.

However, if oxidizing conditions exists at the sediment-water interface there will be little movement of sulfide

into the water above. By the other side, negative redox potential (bellow 0 volt) means that oxygen supply is

to enough to oxidize organic matter, leading to the development of undesired anaerobic bacteria to produce

toxic hydrogen sulfide (H2S) that harms, fragilize or even kill the shrimp, depending on its concentration.

Increasing oxygen concentration on the water, either from paddle wheel aerators and/or blowers are

crucial to revert this undesired condition. After the toxic hydrogen sulfide (H2S) is not anymore founded on

the water and since oxygen level achieve a concentration of at least 3 mg/L, nitrifying bacteria (Nitrosomonas

and Nitrobacter) are suggested to be applied aiming to properly mineralize the organic matter at the sedimentwater interface.

4.2.1 – Extensive Shrimp Farming Systems:

When rearing shrimp on an extensive production system, previous soil treatment with LithoNutri

Acqua® is deeply recommended at a rate not lower than 250 Kg/hectare. In this type of shrimp farming,

normally ponds’ water exchange is high, despite to the vulnerability of pumping contaminated harmful

bacteria water from the neighboring farms when harvesting their own ponds. Hence, even in extensive

farming systems, minimizing water exchange is deeply recommended. Total water alkalinity needs to be

measured at least once a week.

Deeper attention must be given when the water source salinity is lower than 3 ppt. In such cases,

twice a week water alkalinity needs to be measured not only to maintain pH stability, but also to provide

enough Calcium and Magnesium bioavailable carbonates to the ecdysis and osmoregulatory processes.

Our experience enables us to suggest that LithoNutri Micron input of 25 Kg to 50 Kg / hectare once a

week should maintain a low daily pH fluctuation, reflecting the water buffering capacity expressed by the

measure of total water alkalinity.

4.2.2 –Semi-intensive Shrimp Farming Systems:

One step ahead on the way for shrimp farming intensification is the semi-intensive system, when

higher stocking densities are used in smaller ponds and shrimp feed is necessary to supply shrimp nutritional

requirements. Ponds’ natural organisms’ availability are still necessary, and ponds’ trophic chain plays a key

role to achieve better FCR (Feed Conversion Ratio).

Depending on the stocking density used, paddle wheel aerator may be necessary to supply enough

oxygen as well as to destratification of the water column.

Oceana Minerals’ customers using this farming system are suggested to apply 50 Kg to 100 Kg / hectare

/ week of LithoNutri Micron after filling up the ponds (with the previous suggested LithoNutri Micron soil

treatment).

Shrimp farm managers are encouraged to pay attention on the daily pH fluctuations (< 0.5 parts), total

water alkalinity (keeping it higher than 120 mg/L) as well as redox potential measures (above 0.5 volt).

According to these information, LithoNutri Micron inputs can be better managed and, as soon as they start

managing it, adjustments will become easier to adjust the necessary input quantities.

Picture 19: Semi-intensive shrimp pond using LithoNutri Micron for water quality enhancement and boosting

phytoplankton and zooplankton diversity and quantity.

4.2.3 – Intensive and super-intensive shrimp farming systems

It is well known that these systems differentiate from the two previous ones due to the higher shrimp

stoking densities. In both cases (intensive or super intensive), the technological requirements and accurate

water quality parameters must be daily measured and interpreted and managed. Staff members must be well

trained, paddle wheels aerators are mandatory, heterotrophic bacteria probiotic must be added, and shrimp

feed are the main source of nutritional requirements to the farmed shrimp.

Intensive microbiological process on the water column and at the bottom of the ponds are also

characteristics of these systems, where the harmful bacteria load (normally vibrio parahaemolyticus, Vibrio

harveii and their huge number of different strains) increases along the rearing crop and, in many cases,

achieving the quorum sensing stage, when their harmful opportunistic bacteria power leads to diseases

outbreaks, fragilizing the animal’s health and often causing high mortality levels.

The growth of the bacteria load comes along with higher BOD (Biochemical Oxygen Demand) levels,

what means that the environment requires more and more dissolved oxygen on the water. Dissolved oxygen

on the water also affects the pH levels on the water. Supplying dissolved oxygen is mandatory in these

production systems. Once farm managers ensure themselves that DO levels are higher than 3 ppm (ideally

higher than 4ppm), they are suggested to deal with pH water levels and its daily fluctuations. Since shrimps

can absorb bioavailable carbonates through their gills, total water alkalinity decreases all day long and must

be daily checked to avoid big drops on the availability of Ca and Mg for shrimp absorption and use to their

ecdysis process.

Low alkalinity levels negatively impact shrimp osmoregulatory and physiological processes and must

be avoided. LithoNutri Micron composition will not only increase total alkalinity, but it will also stabilize this

essential water quality parameter, especially on intensive and semi-intensive shrimp farming systems,

considered the second most important water quality parameter. Applying LithoNutri Micron into the ponds’

water will also release the main trace minerals required by the shrimp to increase their health status and

achieve higher growth rates.

As we have seen before, mime crying nature is the better way to ensure that the reared shrimps are

as close as possible to their natural environment, and LithoNutri Micron plays a key role to achieve this

purpose, due to its composition, structure, and bioavailability.

Apply LITHONUTRI® Acqua at a rate of 3 – 20 g / m³ / day throughout the entire cycle. Daily dose

escalation should be based on total alkalinity measurements (minimum 120 ppm) and pH fluctuation (pH max

– pH min <. 0,5).

LITHONUTRI® Acqua application on the water, mainly in intensive or super-intensive shrimp farming

systems is not a daily, weekly, bi-weekly, or monthly fixed quantity. It depends on a wide range of biochemical

reactions into the pond. From water temperature to microbiological oxidation processes, to the water oxygen

supply, type, quantity, and strains of probiotic bacteria used into the system, as well as their concentration in

CFU/g – Colony Forming Units per gram. A very impactful ingredient shrimp farmers should pay a lot of

attention is the source of carbon also added into the pond (are farmers sure this carbon source more

commonly used such as molasses, rice bran, corn bran etc. are free from mycotoxins? And if they are not

mycotoxin free?). These are just a few amongst a very large number of known and some still unknown

biochemical and physic-chemical reactions that is happening continuously since you’re preparing the ponds

for a new crop until the shrimp are harvested.

Oceana Minerals’ suggestion for applying LITHONUTRI® Acqua at intensive and super intensive shrimp

farming systems is:

a) Check pond water pH at least twice a day. Ideally, the first check should be before Sun

rises and the second one should be after the Sunset. Depending on the farm size, the

availability of pH (or multi-parameters devices) and well-trained staff to record these

data, shrimp farm managers are encouraged to design an Excel data graphic to “view”

the daily pH fluctuations and an eventual trend to increase this daily pH fluctuations.

b) Very close related to the pH fluctuations is the total water alkalinity. Thus, daily

(ideally) or every two days (not more than that) total alkalinity check MUST be

properly measured. Very often, after shrimps achieve an average body weight of 6 to

8 grams, the non-mineralized organic matter starts to be mineralized by the bacteria,

and this mineralization will consume a lot of dissolved oxygen, releasing and increasing

the H+ concentration on the water, what means that the pH will drop and, thus, the

over H+ concentration need to be neutralized by the water bioavailable calcium

carbonates and magnesium carbonates, what means that enough total alkalinity levels

MUST be available at the ponds’ rearing water.

Picture 20: Litopenaeus vannamei rearing crop on a greenhouse super-intensive geomembrane lined pond

(300 shrimp/m³).

- I. As we have seen on the Table you can find at Item 4.2 – Water Quality Enhancement,

many researchers and institutions related to shrimp farming suggests total water

alkalinity for shrimp farming at 100 mg/L as the minimum level.

II. However, when growing shrimp under stocking densities such as 200 to 300

shrimp/m³ (or even more, such as in BFS – Bio floc Systems, for instance), the

importance of the total water alkalinity levels is even higher, because total water

alkalinity not only neutralizes the H+ concentration to avoid pH fluctuations.

III. Total water alkalinity in intensive and super-intensive shrimp farming systems also

plays a key role on the ecdysis process. As we have learned, we should remember that

shrimp could retain, storage and use the calcium carbonates, magnesium carbonates

and a very large number of microminerals directly from the water. Through their gills,

shrimp retain as many minerals and indispensable molecules as possible from the

water and, after going through their hepatopancreas, shrimp lymphoid organ retains

the rare and essential substances for the well-being of the shrimp and for their further

use.

IV. Throughout the shrimp culture cycle on an intensive and/or super-intensive systems,

where high stocking densities are used, the total water alkalinity plays two different

roles. From one side, it must be enough to avoid pH fluctuations and, by the other

hand it needs to be enough to support the shrimp requirements during the ecdysis

process, which is shrimps’ most stressful process and happens many times throughout

the production cycle. If a pond water cannot supply enough calcium carbonates and

magnesium carbonates, shrimps’ new exoskeleton will not be as strong as they should

be, and their vulnerability to diseases is increased once harmful bacteria can fix

colonies on the tissues right under the fragile new exoskeleton.

c) Some other water quality parameters are also crucial, and directly or indirectly affects

LITHONUTRI® Acqua mode of action. Once we remember that water temperature

directly impacts on the aquatic animals’ behavior, their physiological process and all

physic-chemical and hydrobiological reactions, we can easily conclude that high (29o

C)

or very high-water (29o

C to 32o

C) temperatures leads to a very rapid reactions, the

most important water parameters are also linked with the water temperature, shrimp

eat more feed e produces more feces, the time from one ecdysis process to the next

one is shortened, the bacterial load grows much more quickly, the oxidation processes

are faster and the hole ponds’ environment is, thus, affected.

This is more often found in greenhouses’ ponds), and farm managers and their staff

are suggested to better control water temperature, opening windows, and letting the

humid air environment between the water surface and the greenhouse structure to

flow through.

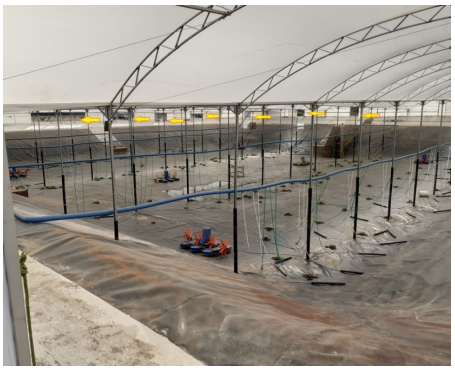

On the picture bellow, you can find an empty greenhouse super-intensive

geomembrane lined pond with some arrows indicating windows used to cool down

the water temperature inside the greenhouse to better control it whenever necessary.

Picture 21: Empty greenhouse super-intensive geomembrane lined pond with paddle wheel aerators and air

diffusion structure.

- d) By the other hand, temperatures between 26o

C to 28o

C are less stressful to the pond’s

ecosystem and considered the optimum range for growing Penaeid shrimp such as L.

vannamei and P. monodom. In such temperature range, biochemical reactions are not

so quicky and much easily to manage.

e) Bellow 26o

C pond water temperature may lead to a much lesser feed intake, less feces

are produced in consequence, and lower growth rates are very common. The

biochemical and physic-chemical reactions happen on an even lower speed and

shrimp farmers in this situation normally set up a strategy to avoid stocking during

these times. In countries like Mexico, for instance, they can only have one crop per

year, since middle October and the early November the temperatures fall very quickly,

and then all shrimp farmers starts their harvest season (except the farmers that uses

greenhouses to grow shrimp all year round).

f) In China, there are many shrimp farms that grows shrimp all year round due to the use

of greenhouses as well. We had the chance to visit shrimp farms growing shrimp with

5o

C (temperature outside the greenhouses) and the water temperature around 26o

C

(inside the greenhouses). Heaters are used only when temperatures drop to levels

below 25o

C).

g) Either in very warm water or at lower water temperatures, different viruses and their

distinct strains normally causes diseases due to the optimal condition to express their

virulence. In Ecuador and Brazil, for instance, very high-water temperatures (>30o

C)

normally come along with IMNV diseases outbreaks, whereas WSSV are much more

aggressive in water temperatures from 24o

C to 26o

C, even when using SPF (Specific

Pathogen Free) post-larvae (in Ecuador). In Brazil, where it is not allowed to import

any kind of crustaceans since 2005, the whole country’s brood stock is susceptible to

vertically contaminate the post-larvae. Genetic improvements have been done since

2005 but, indeed, Brazilian SPF post-larvae are not a real SPF post-larva, even when

Real Time PCR doesn’t find one or more different virus(es) on the samples.

4.3 – Nutritional LITHONUTRI® Acqua Applications

Many efforts and a huge number of investments have been done from the main aquafeed

suppliers world-wide over the last two decades to provide the best possible nutritional aquafeed.

Since fishmeal and fish oil are more and more scarce as the times passes by, the use of plant-based

products has been drastically increasing, bringing along their anti-nutritional factors that are not

always absorbed by the aquatic animals since they cannot produce the necessary enzymes to digest

them.

This is a fact, and IFFO (International Fishmeal and Fish Oil Association) says that this scarcity

has been daily increasing, once much research for humans, for instance, shows that daily Omega 3

supplementation helps prevent heart attacks and is also good for their immune systems. Fishmeal

have also been used for humans, for pet-food and a wide range of different functionalities.

With wild-catch fisheries stagnation since the mid 80’s, aquafeed suppliers have the challenge

to maintain or even increase their products’ portfolio to keep or increase their market share on the

aquafeed business. The worldwide aquaculture is growing in a higher rate comparing to the nutritional

aquafeed quality, leading for alternative ingredients to replace fishmeal and fish oil on their

formulations.

Indeed, a lot of progress have been made over the last years to achieve this goal. Alternative

protein sources such as insect meal (mainly BSF) and Krill meal have been driving this progress with

regards to protein supply, whereas insufficient fish oil is still a big problem, and many microalgae

inland farming start-ups have been cultivating specific high omega 3 microalgae content to support

the needs for aquaculture to keep growing at the rate it needs to supply the protein source for

humankind.

As we have previously seen at this document, LithoNutri Micron is 100% organic certified

seaweed-derived prebiotic and have been successfully used for many aquafeed suppliers to provide

their products with a wide range of essential macro and micro minerals, and to achieve the best

possible phosphorus and calcium ratio to their aquafeed in terms of composition and nutritional

balance.

Aquafeed formulation departments vary a lot amongst feed millers in terms of software and

nutritional matrix. A very common issue is to calculate microminerals’ supplementation. Indeed, the

quality and the availability of the raw material used for aquafeed very seldom calculates the nondigestible ingredients’ bioavailability, what means that LithoNutri Micron supplementation is cost

effective due to its natural bioavailability. Additionally, LithoNutri Micron honey-comb shaped

structure and composition helps beneficial probiotic bacteria and live yeast probiotic to grow,

decreasing the harmful bacteria load due to competitive exclusion and Quorum Sensing inhibition.

Providing a minimum of 32% Ca, 3% Mg, 18 amino acids and 70+ bioavailable microminerals,

LithoNutri Micron not only helps to promote a healthier gut microbiota, but its electrolytic

composition is also linked with the anti-oxidative stress potential, by releasing cationic ions used to

neutralize the ROS (Reactive Oxygen Species), commonly known as free radicals. According to

Figueiredo-Silva et al (2021), although shrimp can absorb some minerals from the aquatic

environment, their feed supplementation is crucial to modern aquaculture production conditions.

Minerals have many physiological functions and are essential in the maintenance of osmotic pressure

and the regulation of pH, hemolymph, and urine.

LithoNutri Micron composition and bioavailability are also important components of

exoskeleton, soft tissues, enzymes, vitamins, hormones, pigments, and it is also essential for muscle

contraction and transmission of nerve impulses (Piedad-Pascual 1989). The ionic composition

generally has a greater impact on shrimp health than salinity (Davis et al. 2004). Whereas sodium (Na)

and potassium (K) are important for osmoregulation function, calcium (Ca) and magnesium (Mg) are

very important to the moulting process and new shell formation (Samocha et al. 2017).

In a recent study carried out by Truong et al. (2020), the macro and trace minerals important

in the diet of juvenile Penaeus monodon were determined. The investigators demonstrated that

inclusions of microminerals such as calcium, magnesium, boron, manganese, selenium, and zinc to the

dietary formula were important for growth, feed conversion efficiency, biomass gain and nutrient

utilization. The mineral requirements and quantities for Penaeid shrimp reported by other

investigators were used in this trial conducted by Truong et al. (2020).

Picture 22: Physiological and osmoregulatory’ process intrinsically dependent of six different microminerals

If the trend for marine shrimp farming to be reared at inland areas with freshwater sources

(sometimes at 0 ppt) increases and is already a reality in many countries like India, Pakistan and

Bangladesh (in Asia), as well as in Mexico, Peru and Brazil (in Latin America), the nutritional challenge

to achieve profitable results is even higher, and LithoNutri Micron composition and bioavailability have

shown to be mandatory to supply minerals requirements.

Indeed, many feed millers have the same shrimp feed supplemented with different LithoNutri

Acqua® percentages of inclusion, which varies from 0.5% to 2.5% of the total composition. Of course, these

feed millers’ profit margins increase a lot depending on the percentages of LithoNutri Micron inclusion on the

feed. At the picture bellow, you can find a headless shrimp where you’ll notice a full healthy hepatopancreas

and its lymphoid organ much bigger than we normally find on marine or brackish waters sources.

The farm from where we collected this sample is supplied by a freshwater river 125 Km far from the

coast with 0,3 ppt salinity and 25 mg/L total alkalinity reared at a stocking density of 80 shrimp/m³ on a

greenhouse geomembrane-lined pond.

Picture 23: Shrimps’ lymphoid organ used as a minerals’ reservoir to be used for ecdysis processes and

physiological activities under challenging water quality parameters.

5 – CONCLUSIONS

This document contains many important information regarding fish and shrimp farming and its

correlation with the wide range of LithoNutri Micron applications. It will also be very helpful to be used

accordingly to our existing and prospect customers’ particularities. Although it can be used as a source of

valuable information, we can more easily find some topics related to different production systems and some

of the main requirements each system normally faces.

This first version of the Oceana Minerals Technical Acqua Guide is much more focused on shrimp

farming. On the following versions of this document, we’ll add some more information about shrimp farming

and, of course, about fish farming with a wider focus on Tilapia farming.

I wish this Oceana Minerals Technical Acqua Guide can help colleagues around the world and I’d like

to hear comments, suggestions and recommendations from the ones who will really read it.

Marcelo Borba

Global Technical Lead – Acqua Oceana Minerals

BQ&Q CORPORATION